No products in the cart.

Forklift Safety

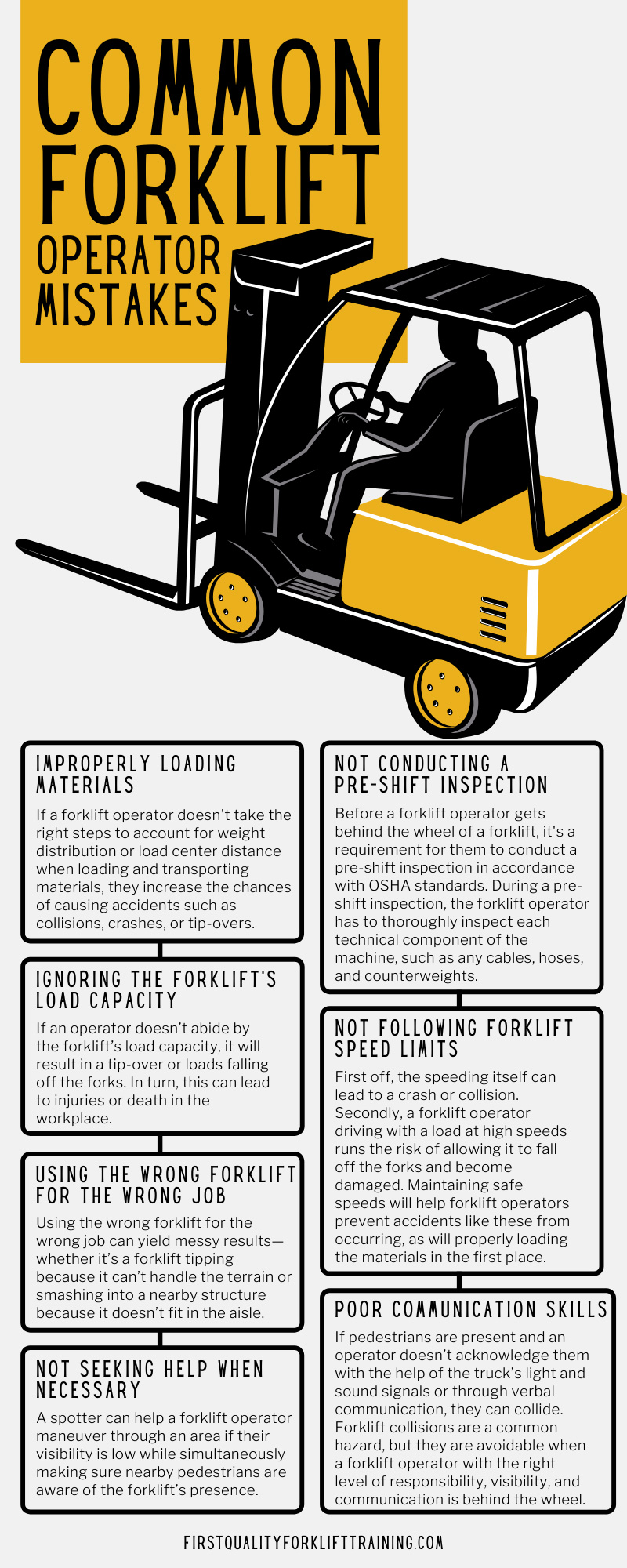

Common Forklift Operator Mistakes

A reliable, certified forklift operator can do wonders for a workplace that requires these machines to complete tasks day-in and day-out. If they can maintain effective workplace safety and efficiency while operating their vehicles, then you should be able to see the results in their work each day. This guide will showcase common forklift operator mistakes that occur in facilities all across the country. That way, you can take the proper steps to ensure they don’t occur in your facility.

Not Conducting a Pre-Shift Inspection

Before a forklift operator gets behind the wheel of a forklift, it’s a requirement for them to conduct a pre-shift inspection in accordance with OSHA standards. During a pre-shift inspection, the forklift operator has to thoroughly inspect each technical component of the machine, such as any cables, hoses, and counterweights. The operator will also have to inspect the fork, mast, and fluid levels of their forklift to ensure it’s ready to go.

The main reason for conducting this inspection is to make sure the forklift isn’t suffering from any damage or in need of maintenance prior to the operator getting behind the wheel. If the operator spots an issue like a leak, damaged forks, or insufficient fuel levels, then they can address it immediately. When operators don’t carry out a pre-shift inspection, they run the risk of getting behind the wheel of faulty machinery. Using faulty machinery in a workplace can lead to accidents that result in property damage, pedestrian injury, or even death.

Poor Communication Skills

To maneuver a forklift around the workplace safely, operators need to be sure that no pedestrians are dangerously close to them. This is where having good communication between employees becomes incredibly vital to workplace safety. If pedestrians are present and an operator doesn’t acknowledge them with the help of the truck’s light and sound signals or through verbal communication, they can collide. Forklift collisions are a common hazard, but they are avoidable when a forklift operator with the right level of responsibility, visibility, and communication is behind the wheel.

Workplaces in which forklifts regularly operate should have signage in designated areas warning pedestrians that these pieces of heavy machinery are nearby and that they should remain alert. Even with this being the case, forklift operators should still be aware of their surroundings and using the proper warning lights/signals to ensure they don’t strike a wandering pedestrian.

Not Following Forklift Speed Limits

A forklift operator who thinks driving at faster speeds equates to better work efficiency should probably go through a refresher course of some kind. This is because driving a forklift through any environment at high speeds is dangerous. As mentioned above, forklift collisions are common for reasons as simple as poor communication and operators driving forklifts too fast.

Additionally, if a forklift operator is speeding through the workplace with materials on their forks, they are creating a handful of hazards. First off, the speeding itself can lead to a crash or collision. Secondly, a forklift operator driving with a load at high speeds runs the risk of allowing it to fall off the forks and become damaged.

Third, during a situation in which driving at high speeds causes a load to fall from the forks, the load can strike an employee, leading to injuries or death. Maintaining safe speeds will help forklift operators prevent accidents like these from occurring, as will properly loading the materials in the first place.

Improperly Loading Materials

Forklift operators need to take special care when loading materials onto the forks of the vehicle. If a forklift operator doesn’t take the right steps to account for weight distribution or load center distance when loading and transporting materials, they increase the chances of causing accidents such as collisions, crashes, or tip-overs. Forklift operators should be aware of the characteristics of their specific forklift, like its load center. Keeping the forklift’s load center, which should be clearly labeled on its data plate, in mind when loading products is a simple step that helps minimize hazards in the workplace.

Ignoring the Forklift’s Load Capacity

The data plate that displays information like forklift load center distances will also clearly label the vehicle’s load capacity. If an operator doesn’t abide by the forklift’s load capacity, it will result in a tip-over or loads falling off the forks. In turn, this can lead to injuries or death in the workplace. Even if the weight of a product is just slightly beyond the forklift’s load capacity, an operator shouldn’t think they can push through it and make it to their destination. Irresponsible actions like this are what cause avoidable accidents.

Not Seeking Help When Necessary

Forklift operators need to optimize visibility at all times to maintain safe driving practices, but realistically, they are bound to experience blinds spots in the workplace. Some forklift operators will try to make it work by themselves, but better, reliable operators will seek out help from a fellow employee. A spotter can help a forklift operator maneuver through an area if their visibility is low while simultaneously making sure nearby pedestrians are aware of the forklift’s presence.

Using the Wrong Forklift for the Wrong Job

There are many types of forklifts used across various industries, but not all of them can complete the same task. Some are better for moving through narrow aisles, while others are specialized for situations involving reaching great heights, driving over rough terrain, and a variety of other factors. Using the wrong forklift for the wrong job can yield messy results—whether it’s a forklift tipping because it can’t handle the terrain or smashing into a nearby structure because it doesn’t fit in the aisle.

Now that you’re more familiar with the most common forklift operator mistakes, you can take the proper steps to ensure they remain far away from your facility. The first step you need to take is providing new hires with forklift training classes so they can receive OSHA certification before working in your facility. To keep forklift operators sharp, you should also consider offering refresher courses to employees who want to refamiliarize themselves with the rules and regulations of the job.